Previously, through our article on the 5 Early Warning Signs of a Failing Construction Project, we explained the shocking discovery made by NCA regarding the risks of building collapse in Nairobi.

There’s no better way to say this, but it seems only 42% of the city’s current buildings make the cut for long-term human habitation.

So, believe it or not- most of the buildings in Kenya are of questionable quality. They can’t withstand the test of time. And most importantly, they are not safe for anyone over the long haul.

Come to think of it, the whole problem is like a continuous game of Russian roulette. You know your building or construction project is potentially vulnerable to structural failure. But, somehow, you just don’t want to think about it.

Yes, that’s right. Most people leave everything to chance by ignoring the hazards, and choosing to believe that the risks don’t necessarily affect them.

However, and sorry to say, the recent unfortunate building collapse incident at a private school on Ngong’ Road is a stark reminder that every single person in Kenya is a potential victim. At least 7 pupils aged between 8 and 15 lost their lives, and more than 59 were injured after their classroom collapsed.

If we additionally considered other similar building collapse incidences that have occurred in Kenya over the past decade, the death toll would stretch into the thousands. The financial losses, on the other hand, would cumulatively add up to billions of Kenya shillings. (Read Average Construction Costs in Kenya)

So, let’s face it. The whole thing is a crisis. And no, government bodies in the construction sector will not safeguard your building or project against structural failure. Although they are often criticized for negligence, the truth of the matter is, it’ll probably take decades for Kenya to implement fool-proof policies for preventing building collapse.

In the meantime, expect the number of potential hazards to increase as urban centers grow exponentially and the country’s climate continues to change.

Now, the fact is, it all comes down to the measures you’re willing to take to safeguard your construction project. And to help you with that here are the basic tricks for preventing structural failure and possible building collapse.

Preventing Structural Failure of Concrete in Your Construction Project

The structural soundness of the concrete elements in your building depends on not only the casting process, but also design and installation. Even the slightest mistake in any of these stages could substantially compromise the entire structure, and eventually trigger building collapse.

That said, some of the critical factors you should pay close attention to include:

Relative Humidity

During the curing process, concrete should not be left in a dry environment. Instead, you should protect it adequately by maintaining 100% relative humidity.

Wondering why?

Well, in simple terms, the compressive strength of concrete is built progressively throughout the curing period by continuous hydration reactions. And since water is main the chemical element required when it comes to that, you should provide enough of it to keep your concrete members soaked.

Temperature

Hydration reactions also tend to respond to different temperature conditions.

In essence, the higher the curing temperature, the higher the corresponding reaction rate. Therefore, by increasing your concrete’s temperature, you’ll ultimately speed up the curing and hardening process.

That explains why the average curing period for concrete in, say Mombasa or Isiolo, is shorter than in Limuru or Nyandarua.

But, here’s the kicker. A faster hydration reaction isn’t always a good thing. It’s been proven that although high temperatures speed up the curing process, the compressive strength of the concrete is compromised at the end of the day.

Why is that so?

Well, in short, fast hydration reactions increase the porosity of concrete and, consequently, weaken the bond between its particles.

So, what’s the best temperature for pouring and curing concrete?

10 to 30 degrees Celsius is the optimum temperature range. Anything below 5 degrees Celsius or above 37 degrees Celsius increases the risk of building collapse. And that’s why construction projects in extremely hot areas like Dubai are occasionally forced to use ice water while mixing concrete.

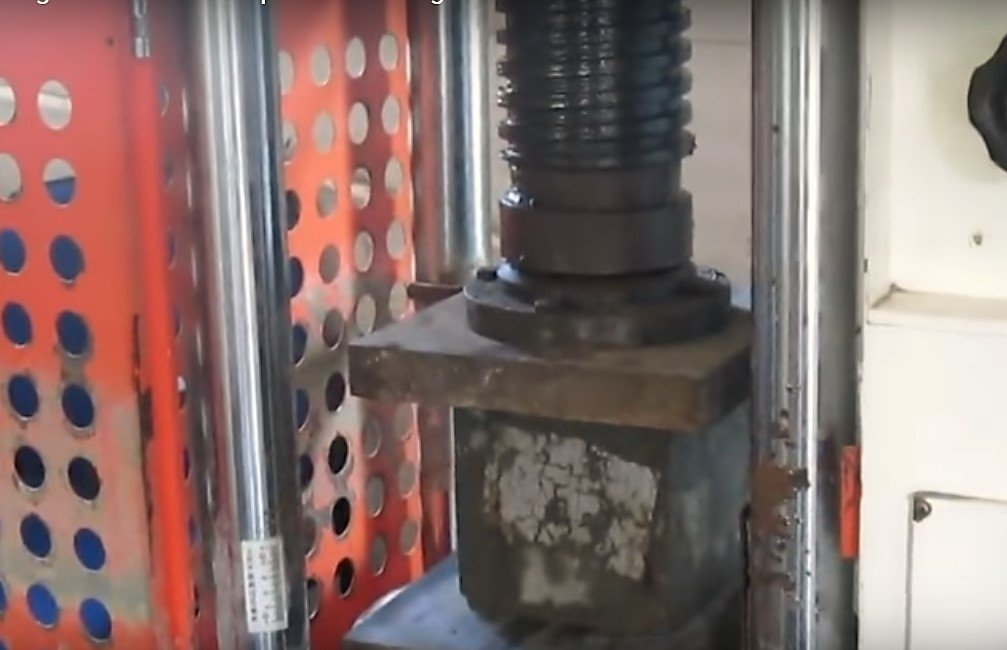

Concrete Compaction

Concrete compaction, which is otherwise known locally as “vibrating”, is one process you can’t avoid in your construction project if you need optimal strength. The goal here is to eliminate trapped air and make the concrete denser, stiffer, and homogeneous.

In the end, comprehensive compaction enhances not only the strength and durability of concrete, but also the bond between concrete and its reinforcement bars.

Poorly compacted concrete, on the other hand, hardens while leaving large air spaces- which ultimately compromise the structural integrity of a building. A trapped air volume of 10%, for instance, translates to 30%-40% less concrete strength- which could ultimately trigger building collapse.

Don’t get me wrong, though. I’m not advising you to overdo your compaction. Not at all. Interestingly, it turns out that such a move could be detrimental to your building’s structural stability, due to something we call concrete segregation.

Now, to prevent that, this is how you should compact or vibrate the concrete in your construction project…

If you’re using a needle vibrator, insert the needle vertically into the poured concrete, and then compact it for not more than 15 seconds. Hold the needle in place until all the air bubbles escape, before proceeding to a different section.

The ideal spacing between the insertions should be 15cm for a 20mm needle vibrator, and 30cm for a 40mm needle vibrator. Proceed systematically through each section, and avoid placing the vibrator needle directly on the concrete’s reinforcement bars.

Curing Period

In an optimal temperature environment with 100% relative humidity, the level of hydration is directly proportional to the amount of time concrete is left to cure. That means the longer the curing period, the stronger the concrete eventually becomes- which translates to lower building collapse risks.

Ok, but can you possibly hydrate your concrete for months?

Well, of course you can. But, here’s the thing. Anything more than 1 month is redundant. It typically takes about four weeks (28 days) for concrete to achieve its ideal structural strength.

So, for now, forget about the 21 days that local fundis commonly advise for concrete curing. Although concrete solidifies to a reasonable degree in three weeks, it requires additional time to complete its hydration reactions.

Aggregate to Cement Ratio

Generally, concrete is a mixture of cement, water, coarse aggregate (gravel or ballast), and fine aggregate (sand).

As you mix them, always remember that:

- The lower the ratio of water to cement, the more the strength of the concrete in the end. It’s worth noting, however, that less water translates to reduced concrete workability.

- The water to cement ratio drops when you increase the amount of cement without adding water.

- At a constant volume, an increase in the cement-sand ratio translates to a corresponding increase in the surface area of the concrete.

- Despite the increase in the concrete’s surface area, its water demand remains the same to maintain workability.

In a nutshell, here’s how the aggregate to cement ratio affects your concrete’s strength and workability:

In a nutshell, here’s how the aggregate to cement ratio affects your concrete’s strength and workability:

So, what’s the best mix ratio for building projects in Kenya?

The fact is, the mix ratio depends on the intended compressive strength of concrete as well as your local bylaws. Currently, building projects in Kenya are typically required to proceed with a concrete grade of at least C20 or C25.

However, between the two, C20 (or M15) is the one that’s widely considered to be the standard grade. In layman terms, C20 basically translates to medium strength concrete, which should withstand a compressive force of 20 N/mm2 after 28 days of curing.

The concrete mix ratio here is 1:2:4 (cement to sand to ballast).

Now, in case you’re wondering, the difference between Class C and Class M is the shape of the final test sample. C describes cylindrical test samples while M describes cube test samples.

Eventually, a sample in the shape of a cylinder should withstand about 80% of the compressive force that a cube sample of similar concrete strength can endure. Hence, C20 and M15 grades usually apply the same mix ratio.

That said, here are the details of other concrete mix grades that Kenyan architects and engineers commonly use in their construction projects to minimize the risks of building collapse:

- Concrete Grade C10 (Equivalent to M7.5) – is the weakest and has a mix ratio of 1:4:8. Therefore, it’s typically used for non-structural work like pathways, patio slabs, etc.

- Concrete Grade C15 – Has a mix ratio of 1:2:5 and it can be used for floor blinding, pavement curbs, etc.

- Concrete Grade C20 (Equivalent to M15) – The required mix ratio is 1:2:4 and it’s ideal for internal floor slabs, driveways, garages, workshop bases, and foundations.

- Concrete Grade M20 – Has a mix ratio of 1:1.5:3 and it’s suitable for thin columns as well as high strength walls.

- Concrete Grade C25 (Equivalent to M25) – With a mix ratio of 1:1:2, it’s considerably stronger than Grade C20. So, it’s typically used for high strength columns, beams, foundations, and slabs.

- Concrete Grade C30 – Has a mix ratio of 1:2:3, which makes it much more durable and weather-resistant than the preceding concrete classes. Plus, considering it can handle heavy vehicular traffic, C30 is usually used for roadways and pathways.

So, how can you check and confirm that your contractor has adhered to the exact mix grade specified in your building’s structural plans?

Well, quite simple actually. Just have your project manager conduct cube tests during the casting and curing period. That alone should give you the precise compressive strength figures of the concrete used in the construction project.

Aggregate Ratios

Adjusting the ratio of even one of the aggregates in your concrete mix could trigger a chain of events that could ultimately comprise the compressive strength of your building, and possibly lead to collapse.

Now, imagine you decide to finish all the extra sand in your construction project by forcing it into the concrete mixes.

Or, maybe you happen to be a victim, like many others, of construction site theft.

It’s now common knowledge that unscrupulous fundis and contractors are fond of stealing, among other items, cement bags. Then to make up for the subsequent deficit, they usually increase the proportions of sand in their concrete mixes. (Read The Harsh Realities of Construction Materials Theft)

Whichever the case, here’s the thing about changing the ratios. If you decide to increase the proportion of fine aggregate to coarse aggregate, the first thing you’ll notice is a corresponding increase in the cumulative aggregate surface area.

And the problem with a high aggregate surface area is the thirst it comes with. So, expect the concrete mix’s water demand to go up.

At that point, you’ll need to introduce more water to enhance the concrete’s workability. So, of course, the water-cement ratio will consequently increase.

And what does that mean?

Well, in short, the final result is reduced compressive strength plus an increased risk of possible structural failure and building collapse.

Quality of Cement, Aggregates, and Water

Of course we’d all prefer to use the cheapest cement, sand, and ballast we can possibly find. But, unfortunately, as Integrum has established over the years, choosing these components randomly could be detrimental to your construction project.

Take cement, for instance. Its suitability and quality aren’t dependent on just the branding. You have to go beyond that and assess the most important bit- its strength class as stated on the package. The figures you’ll see here indicate the cement’s overall performance in terms of its expected compressive strength, setting time, and curing mechanism.

Here are the meanings of some of the popular cement classes you’ll find recommended by architects and engineers in Kenya:

- MC 22.5X – “MC” translates to masonry cement, while “X” means the cement lacks a trapping agent. Therefore, it’s ideal for soil stabilized blocks, screeds, smooth plasters, and mortars. You should not use this class on your structural elements.

- 32.5N – “N” refers to normal strength cement. It’s ideal for the structural elements in your construction projects that may not particularly need high initial strength during the curing process.

- 32.5R – Unlike the “N” class cement, “R” here means rapid strength. Or in simple terms, you can expect this class of cement to set fast and gain high strength early during the curing process.

- 42.5N – Can achieve substantially higher compressive strength compared to 32.5 class cement. That’s why it’s typically used for structural elements that are designed to support fairly heavy loads.

For better performance, you might want to consider higher classes like 42.5R, 52.5N, or 52.5R. Please note, however, that these are mostly used in exceptionally demanding projects like highways and bridges.

Now, adjacent to the strength class, you’ll find a CEM value that denotes the cement’s ingredients as follows:

- CEM I – Portland cement.

- CEM II – Portland Composite cement, Portland Limestone cement, Portland Burntshale cement, Portland Fly Ash cement, Portland Pozzolana cement, Portland Silicafume cement, and Portland Slag cement.

- CEM III – Blast furnace cement.

- CEM IV – Pozzolanic cement.

- CEM V – Composite cement.

When it comes to the quality of aggregates, you should analyze their performance capabilities based on their particle composition, texture, shape, and size. The higher the ratio of salts (sulphates and chlorides), the lower the final compressive strength of the concrete, and the higher the risks of building collapse.

Water, on the other hand, has a strict quality standard on its level of purity. Even the slightest form of dirt is unacceptable if you intend to achieve the best possible concrete strength.

Therefore, you should only mix your concrete with water that’s clean enough for human consumption.

The Bottom Line – Safeguarding Your Construction Project Against Building Collapse

With these pointers, you should be in a much better position to control the quality and strength of concrete in your construction project.

But, remember- there are numerous variables you should factor in to safeguard your construction project and minimize the risks of building collapse. The best people to advise you accordingly when it comes to that are professional architects, engineers, as well as project managers.

All in all, the best strategy for safeguarding a construction project in Kenya is leveraging reputable professionals for comprehensive quality assurance and quality control. Besides, in the unlikely event your building happens to collapse, you’ll be compensated appropriately by their professional indemnity insurance.

In the meantime, feel free to get in touch with Integrum in case of any queries or concerns regarding your construction project. Our project managers, architects, and engineers will be glad to assist you.

This information has been very helpful and educative.